Nanoindentation Tester ENT-5

Product name in China: “ELIONIX-5”

New

Measurement and Analysis System

Applicable to variable kind of materials

・Thin film materials such as plating and hard films

・Resin materials, film materials

・Extremely thin film such as DLC

・Functional resin film and surface modification film

・Microparticles and powder materials

Features of ENT-5

・5th generation “ENT”

・High data reproducibility by suppressing disturbance in the measurement environment

・Because it is made in Japan, it has a friendly GUI.

・Supports a wide range of test loads from 0.5 μN to 2,000 mN

Nanoindentation test

・Mechanical properties such as hardness and elastic modulus of thin films, extreme surfaces, and minute regions can be obtained.

・Indentation observation is not required because the characteristics are obtained by analyzing the load-displacement curve.

・Compliant with ISO 14577-1/JIS Z 2255

Data reproducibility and maintainability

1, Temperature control mechanism

・Suppresses thermal expansion of samples and testing machines

・Temperature control inside the windshield at ±0.1℃

・Low thermal expansion material (nobinite) is used for measuring parts.

・Blocks the influence of external air currents

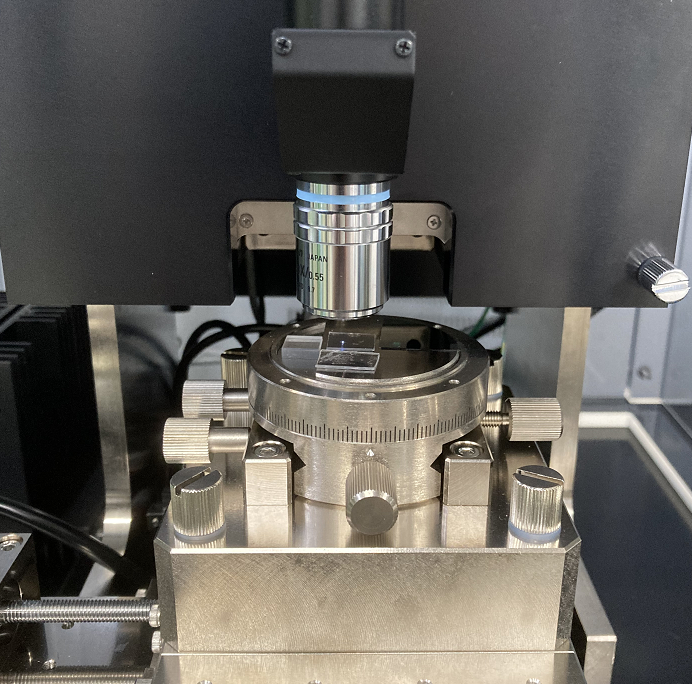

2, High precision positioning stage

・Adopted high-precision stage technology for electron beam lithography equipment developed in-house

・Positioning possible in 0.1μm steps

・Measuring any location with an observation magnification of 2,000x (when using a standard objective lens of 20x and digital zoom)

3, Anti-vibration mechanism

・High-precision wedge-shaped stage that is resistant to vibration

・Equipped with an active anti-vibration table as standard

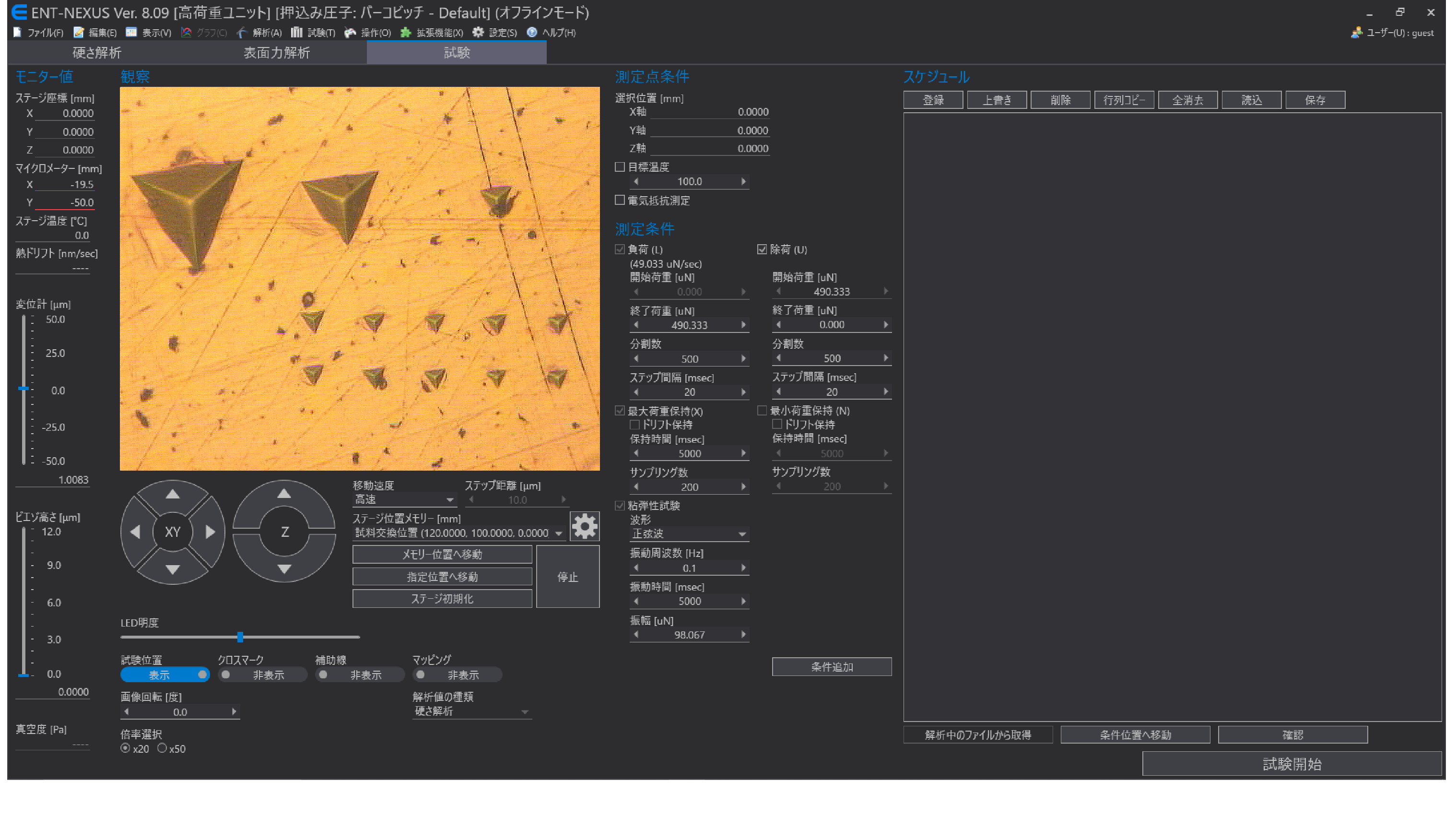

4, Software

・Auxiliary functions such as indenter tip correction, temperature drift correction, and reminders for daily inspection

・ Operability cultivated through many years of experience

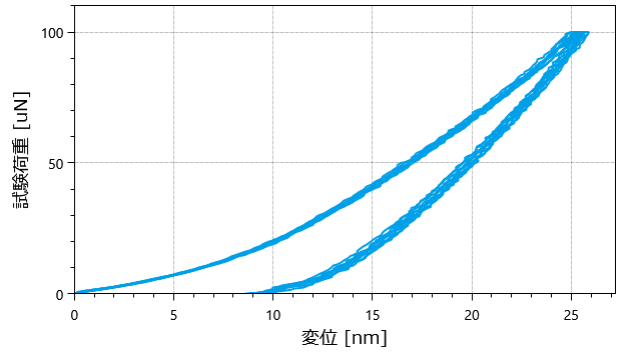

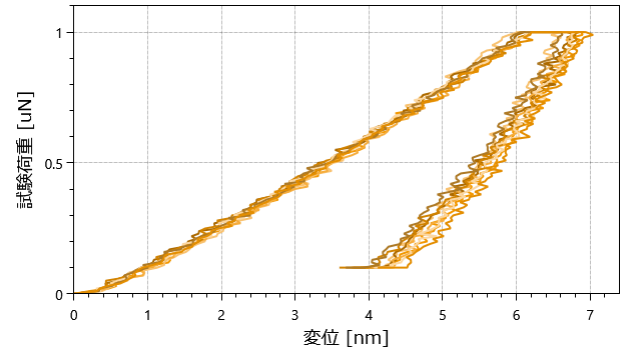

5, Data reproducibility

・Data reproducibility is improved with a mechanism that suppresses the effects of disturbances such as vibration and temperature changes.

・Stable data acquisition is possible even in continuous measurement

6, Maintainability

・Easy replacement of high load unit and low load unit

・Equipment downtime is reduced by calibrating equipment by exchanging units.

Load unit

High load unit measurement example [Fused quartz]

(Test load: 100μN 9 times overlapping)

Low load unit measurement example [Resist]

(Test load: 1μN 9 times overlapping)

▶ High load unit

・Testing from 5 μN to 2 N is possible.

・Compatible with hardness tests for a wide range of materials, from metallic materials to polymeric materials.

▶ Low load unit

・Corresponds to 0.5 μN to 10 mN.

・Soft materials (elastic modulus: several GPa or less) and

Excellent repeatability and stability can be obtained for measurements with an indentation depth of 10 nm or less.

・Functional resins such as UV curable resins, low-k films, elastic materials such as silicone rubber, and ultra-thin hard films such as DLC films

Suitable for mechanical property evaluation.

▶ Dynamic test

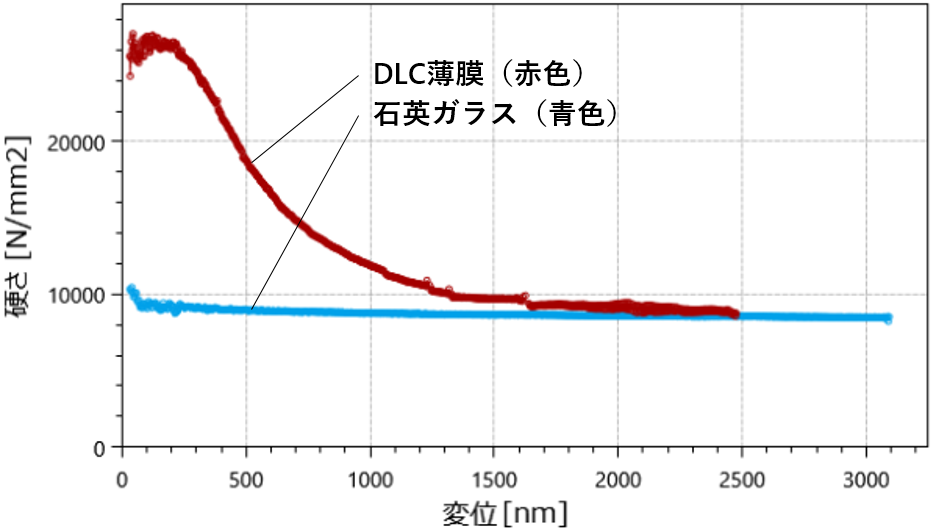

It is possible to continuously acquire the hardness distribution in the indentation depth direction by performing the test while applying minute vibrations to the indenter.

・Sample: Quartz glass (blue), DLC film (red) ・Test result: Quartz glass shows almost constant hardness regardless of the indentation depth. On the other hand, in the case of the DLC sample, it can be seen that the hardness of the DLC film on the surface and the hardness of the base material change continuously while being affected by the base material.

| Load/load resolution | High load unit: 5 μN to 2,000 mN / 5 nN Low force unit: 0.5 μN to 10 mN / 0.03 nN | ||||

|---|---|---|---|---|---|

| Loading method | Electromagnetic force | ||||

| Measuring range | ± 50 μm | ||||

| Measurement resolution | 0.3 pm | ||||

| Measurement method | Optical | ||||

| Sample size (typical value) | φ 50 x t 3.5 mm | ||||

| Measurable area | X 50, Y 40 mm | ||||

| Minimum movement step | 0.1 μm | ||||

| Heating holder | Heavy-duty unit: maximum heating temperature 250 °C Low load unit: maximum heating temperature 180 °C | ||||

|---|---|---|---|---|---|

| Resin embedding holder | Holder for resin-embedded samples for cross-sectional observation, etc. | ||||

| Custom-made holders and jigs | We will design and manufacture according to the sample. | ||||

| Viscoelasticity test | A load is generated at an arbitrary frequency while the indenter is pressed into the sample with a constant load, Storage modulus (E'), loss modulus (E"), loss modulus (tanδ) can be measured. Also, by using a heating stage together, it is possible to evaluate the glass transition point (Tg). | ||||

|---|---|---|---|---|---|

| Underwater test | It is possible to perform hardness tests in water. | ||||

| Compressive strength of micro particles test (High load unit only) | This method uses a flat indenter to compress or crush fine particles and measure their strength. | ||||