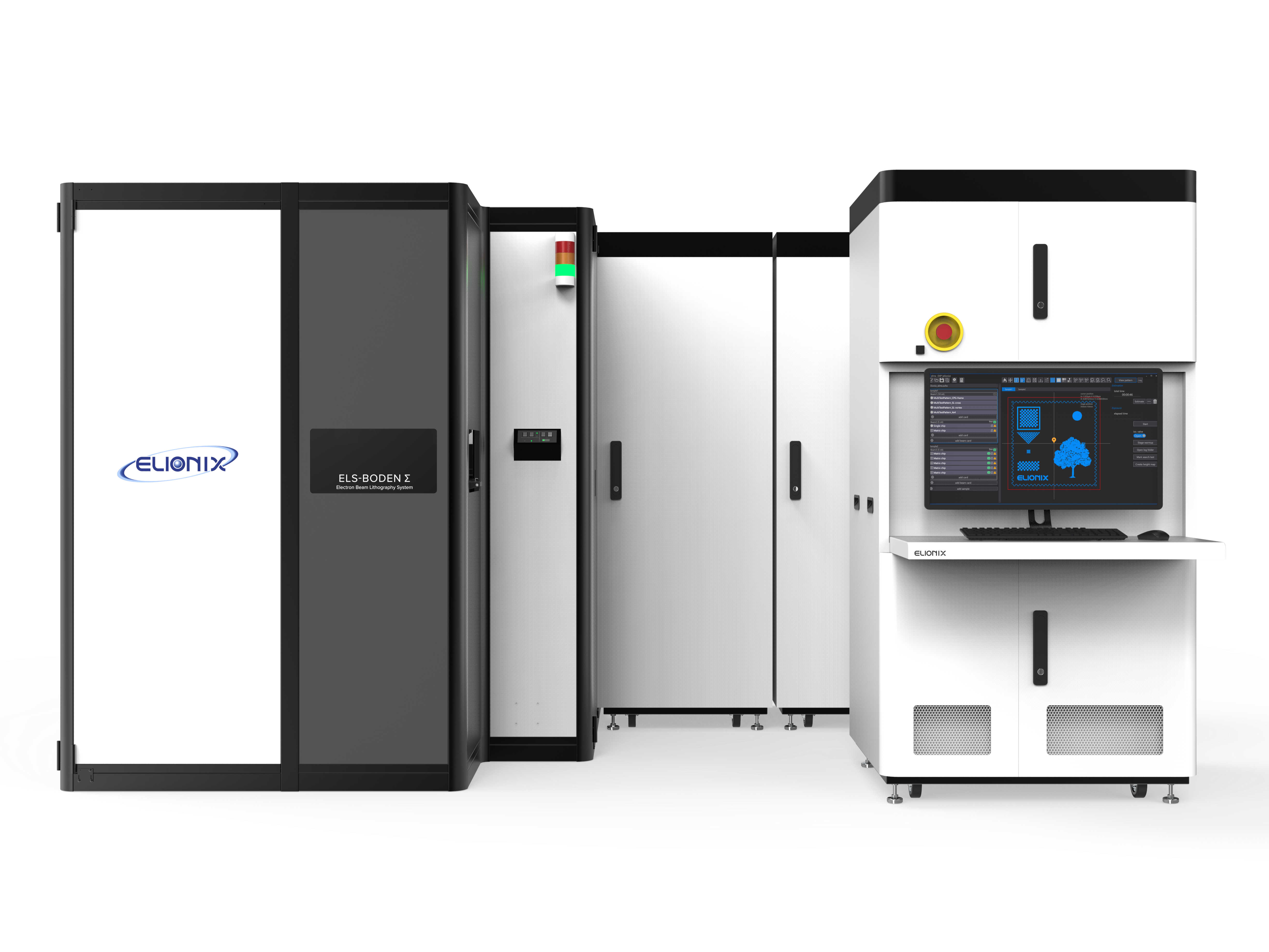

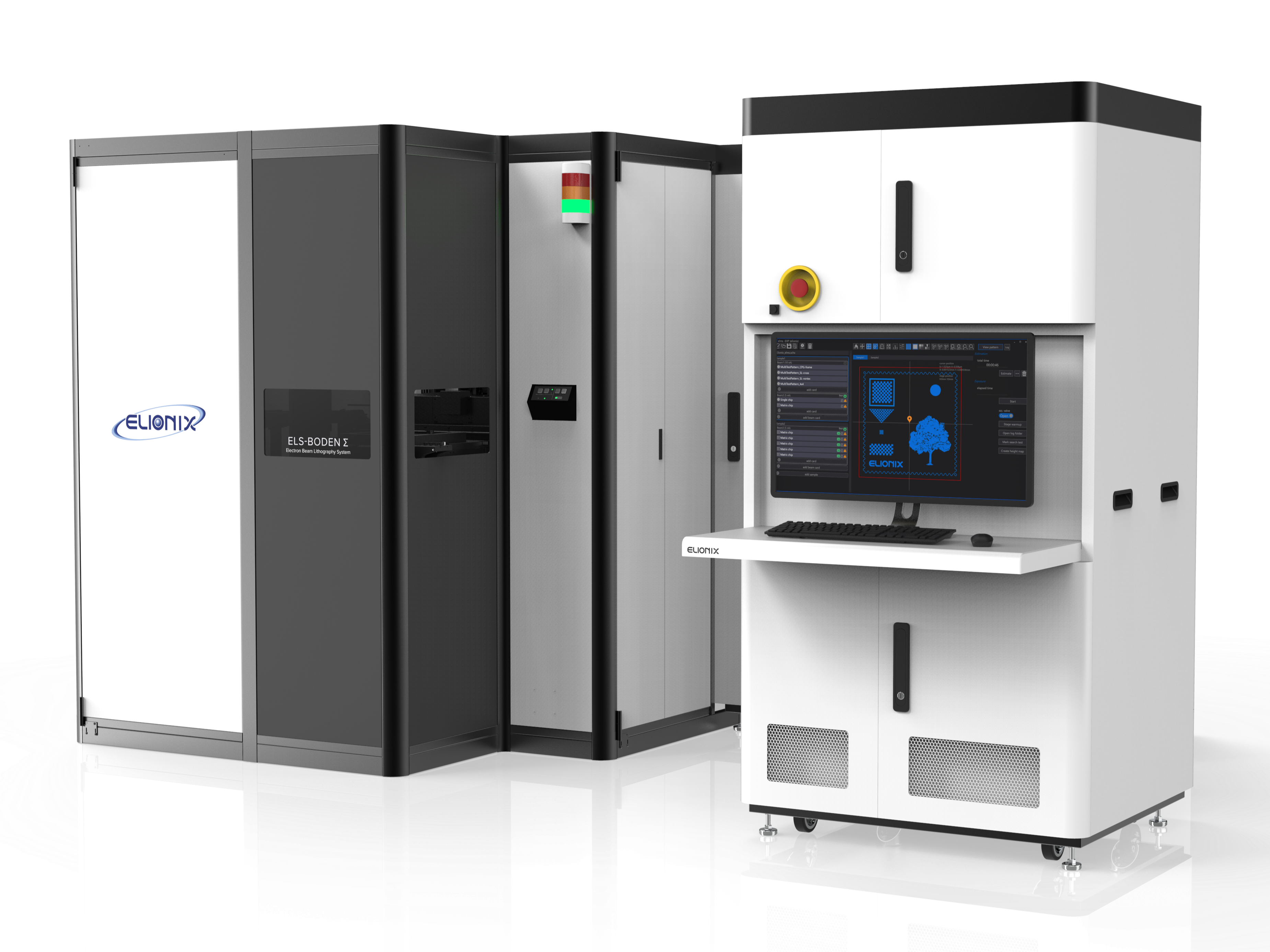

Electron Beam Lithography System ELS-BODEN Σ

New

Nanofabrication System

World’s Fastest Scan Clock 400 MHz

Previously, for large current writing, shot pitch had to be set large to strike a balance between minimum dose time and optimized dose amount.The 400 MHz scan clock makes it possible to shorten the minimum dose time by 75% and therefore to expose with large beam current and narrow pitch. This enables faster and higher quality exposures.

Faster Stage Speed

The number of stage movements is increased when many writing fields are exposed or alignment marks are repeatedly detected during exposure. Stage driving speed is vital for keeping exposure time short. The BODEN∑ uses a high speed stage, which enables higher throughput for manufacturing application.

Reduction of External Disturbance

Enclosure and EMI canceller are standard with the system. This reduces the envirnmental disturbance to realize stable processes.

| TFE Filament | ZrO/W Thermal field emitter | ||||

|---|---|---|---|---|---|

| Acceleration Voltage | 50 kV | 100 kV | 125 kV | 150 kV | |

| Beam Current | 1 nA ~ 800 nA | 20 pA ~ 100 nA | 5 pA ~ 100 nA | 5 pA ~ 100 nA | |

| Minimum Beam Diameter | Ø 2.8 nm | Ø 1.8 nm | Ø 1.7 nm | Ø 1.5 nm | |

| Standard Field Size | 1000 μm□ | 1000 μm□ | 500 μm□ | 500 μm□ | |

| Min./Max. Field Size | Min. 100 μm □ Max. ( Option ) 3000 μm□ | ||||

| Scan Clock | Max. 400 MHz | ||||

| Shot Pitch | Min. 0.2 nm | ||||

| Max. Sample Size | 8” Wafer / 12” Wafer | ||||

| Max. Exposure F/S | 200 mm x 200 mm / 300 mm x 300 mm | ||||

| Loading Mechanism | Single AutoLoader Robot Loader | ||||

| Software | elms • Beam adjustment function • Drawing schedule function • Pattern data conversion function • Account management • Python scripting | ||||

Sales Headquarters (Hachioji City, Tokyo)

Hours: Monday-Friday 8:30-17:30

Except Weekends, National Holidays, and Year-end and New Year Holidays